Motors

Search

Industrial Motors

In industrial motors custom engineering, quality is crucial. Industrial motors drive machinery in various applications, impacting productivity and efficiency.

Here's why quality matters:

- Downtime Costs: High-quality motors withstand demanding conditions, reducing unexpected breakdowns.

- Energy Efficiency: Quality motors optimize energy use, cutting operational costs.

- Precision: They ensure consistent speed and torque for accurate manufacturing processes.

- Durability: Quality components extend motor lifespan, reducing replacements and expenses.

- Safety: Reliable motors minimize accidents and malfunctions.

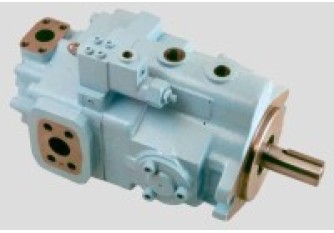

Understanding Industrial Motors

Industrial motors convert electrical energy into mechanical energy, used across industries like manufacturing and transportation. Key components include:

- Stator: Houses coils, generating a rotating magnetic field.

- Rotor: Interacts with the stator's field, causing rotation.

- Output Shaft: Transfers mechanical energy to the load.

- Bearings: Support the shaft for smooth rotation.

Types of Industrial Motors

Choose based on needs:

- AC Motors: Reliable and adaptable, including synchronous and asynchronous types.

- DC Motors: Offer precise speed control for steady motion.

- Servo Motors: High precision and rapid response, ideal for robotics.

- Stepper Motors: Move in discrete steps for precise positioning.

- Brushless Motors: Efficient and durable, suitable for various applications.

Show more

Hide